Manufacturing in RCC Construction Prefabricated rebars

Redefining rebar placement, our team is working with ambitious clients who want to define the future

Prefabricated Reinforcing Bar Products Devoran Metals

January 14, 2020 Concrete Reinforcing Steel Institute (CRSI) Saad Salim/Unsplash The Concrete Reinforcing Steel Institute (CRSI) recently released its newly updated 10th edition of Placing.

Rebar Prefabricated Rebar Elements Rebar Steel Ireland Coen Steel

Embracing the Future of Construction: Automated Rebar Prefabrication - the advantages of BAMTEC®.. Embracing the Future of Construction: Automated Rebar Prefabrication with BAMTEC®As the construction industry continues to evolve, we are witnessing a groundbreaking shift in how we approach traditional practices. One such innovation that's revolutionizing the way we build is Automated Rebar.

High tensile Reinforcing Steel Rebar / Mesh Prefabricated Buildings Kits

2 The Lombardy Region also features several road axes characterized by dramatic traffic volumes. Figure 3 shows average vehicular fluxes in the rush hours on the main highways, in which the great

Rebar Beam Cage The Best Picture Of Beam

'Rebar Prefabrication' is one of the key focus areas in Toggle's mission to build world-class robotics and automation solutions for a wide range of physical fabrication and assembly applications in large-scale urban and infrastructure construction. 2. Why did you start Toggle, and what was the motivation?

Prefabricated Rebar Cages, Bend Reinforcing, Mesh, Auckland Reinforcing

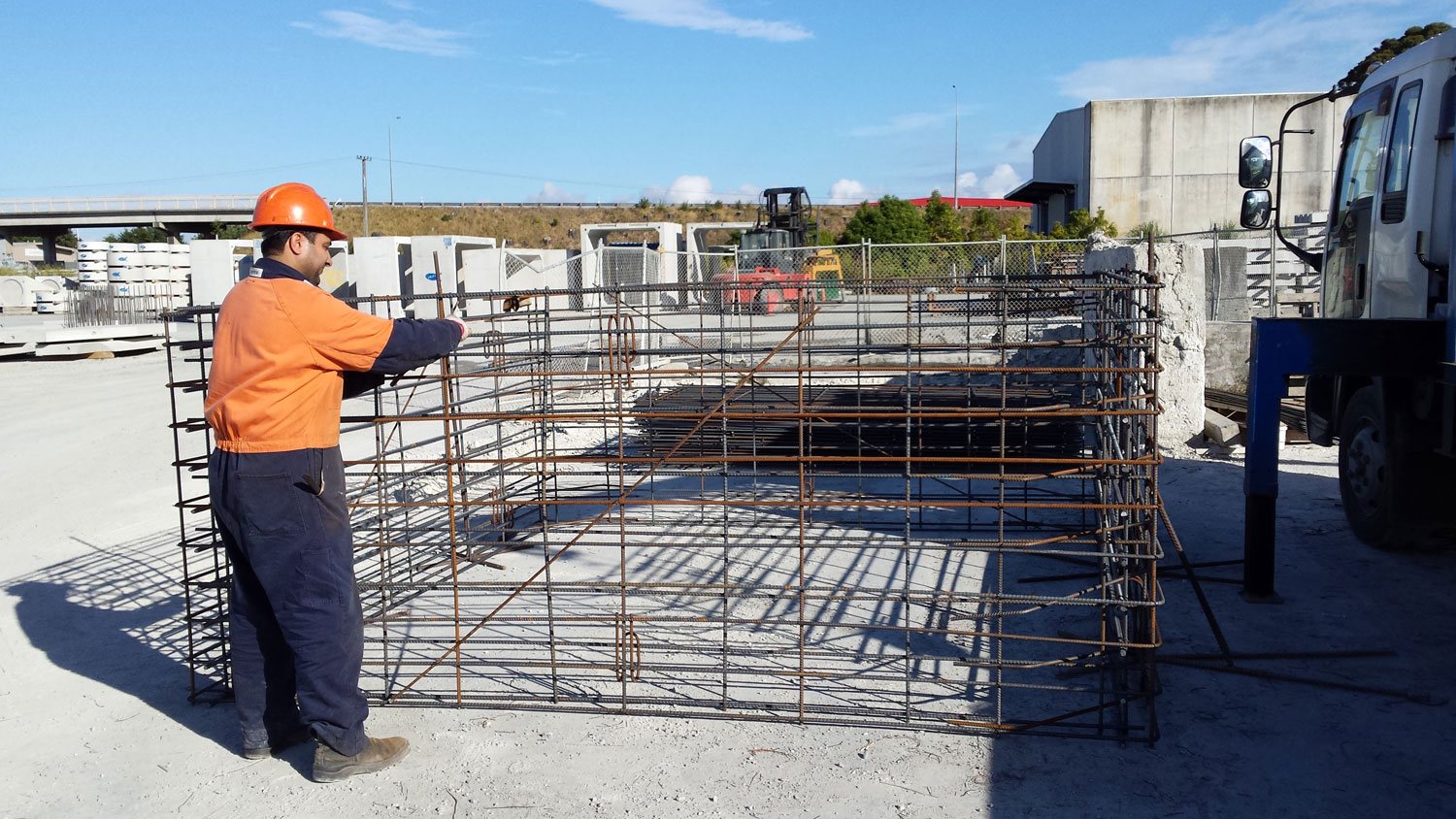

Pre-fabrication provides solutions to problems that traditional rebar placement presents. In order to reduce construction time, lower project costs, and keep workers safe, prefabricated rebar cages (PRCs) are built in fabrication yards on site, or in a remote location and then transported to the jobsite. These innovations have the potential to.

Prefabrication HRC Europe

Projects that need a lot of custom cuts and bends can also benefit from the economies of scale and quality of pre-fabricated rebar. If you're interested in using pre-fabricated rebars for your next project, then contact Bolsinger Rebar today. To book an appointment, call (563) 500-6191 or email [email protected].

Barrier Fencing Mesh Devoran Metals Fachadas arquitectonicas

Similarly, Flux cored welding of A706 rebar is done using E80T1-C (E8XTX-X) type cored wire. Welding preheat temperature for A706 rebar depends on the carbon equivalent of the rebar and its thickness and should be done as follow: Upto 0.40% Carbon Equivalent: No preheat. From 0.40% to 0.65% Carbon Equivalent: a preheat in the range of 200 °F.

Prefabricated Reinforcing Steel Rebar / Steel Buildings Kits

Rebar fabrication is the process of producing reinforcement bars, also known as rebar, used in reinforced concrete structures. These steel bars provide reinforcement and tensile strength to concrete, enhancing its durability and resistance to cracking and structural failure.

Rebar Prefabricated Rebar Elements Rebar Steel Ireland Coen Steel

Established in 1985, PJ's Rebar is a family-owned independent rebar fabricator specializing in preassembled rebar and other reinforcing products for concrete, masonry, precast, drilling, and rebar installation contractors throughout the West Coast. With our 6-acre facility located in Fremont, CA and our secondary facility located in Turlock.

Prefabricated Rebar Elements Coen Steel

Fabrication Rebar Fabrication Paving Dowels & Baskets Post Tension Cable Anchor Bolt Cages Performance Steel TruSHIELD TruSTRENGTH TruWEAR Construction Services Products & Accessories Tilt Wall Formwork Equipment Rental Fence Posts Tensar Geopier Supplier Zone Indirect Goods and Services

What Are Prefabricated Rebar Cages and Why Do You Need Them?

Get Nucor Harris Rebar's National Strength, Local Service Working for you! Watch our video for the complete story. Harris Rebar carefully selects the location of our rebar fabrication facilities to suit a growing customer base. The selection of rebar fabrication sites provides Harris Rebar customers with the convenience of a local shop and.

Rebar Prefabricated Rebar Elements Rebar Steel Ireland Coen Steel

1. Standardized and prefabricated components 2. (Semi-)automated construction 55 "BIM-based Rebar Design Optimization and Prefabrication Automation" -Jack Cheng, CM Chan, Vincent Gan Background of the Project • Hong Kong has policy to support offsite prefabrication.

Prefabricated Reinforcing Steel Bar Rebar High Seismic Compressive

To develop an automated BIM-based framework to generate the rebar detail drawings and factory machine codes for rebar prefabrication . Description. In this project, the research team has developed a novel BIM-based approach for automated clash-free rebar design optimisation. A highly specialised optimisation program and parametric clash.

Automated rebar prefabrication startup raises 8 million in Series A

Slope not exceeding 1 (Horizontal) : 6 (Vertical) as per IS456:2000 in column rebar at splice location. Fig 6 (s) : Column rebars. Fig 7 (s) : Proper mandrel dia used for bending rebar Fig 8 (s) : Stirrup manufacturing: Wrong & correct practise. A cost comparison for rebar cut & bent at site vs prefabricated rebar is being given for reference:

Prefabricated Rebar Cages, Bend Reinforcing, Mesh, Auckland Reinforcing

Two-dimensional rebar mats and three-dimensional rebar cages are prefabricated horizontally at grade by professional ironworkers, laterally translated, and tripped to a vertical position to simulate the construction sequence based on the results from an industry survey.